Waga Energy, the Waste Commission of Scott County, and Linwood Mining and Minerals are proud to announce the successful start-up of a Renewable Natural Gas (RNG) facility using WAGABOX® technology at the Scott Area Landfill in Davenport, Iowa. This landmark project brings locally produced renewable energy to the community while significantly reducing greenhouse gas emissions.

With an installed capacity of more than 205,000 MMBtu of RNG per year, the new facility will generate the energy equivalent of 1.5 million gallons of diesel fuel. By replacing fossil fuels, it will avoid approximately 15,800 tons of CO₂ equivalent emissions annually, helping advance the fight against climate change.

The Scott Area Landfill is operated by the Waste Commission of Scott County on a site leased from Linwood Mining and Minerals. The landfill processes around 185,000 tons of waste each year from 17 municipalities across Scott County. By transforming landfill gas into a valuable energy source, the project demonstrates the power of innovation and collaboration to turn waste into a clean, circular energy solution.

Scott Area Landfill

Established in the late 1970’s, the Scott Area Landfill serves Davenport and the surrounding communities, managing regional waste with modern environmental systems and supporting local sustainability efforts. The site now plays a key role in producing locally sourced renewable natural gas for the region.

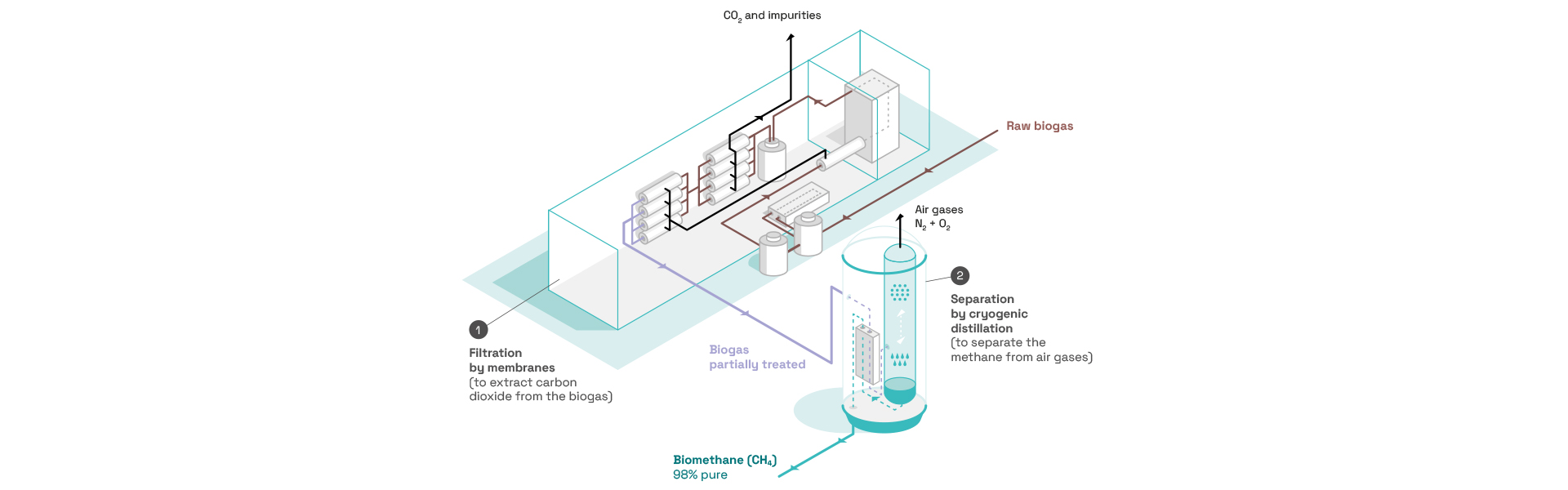

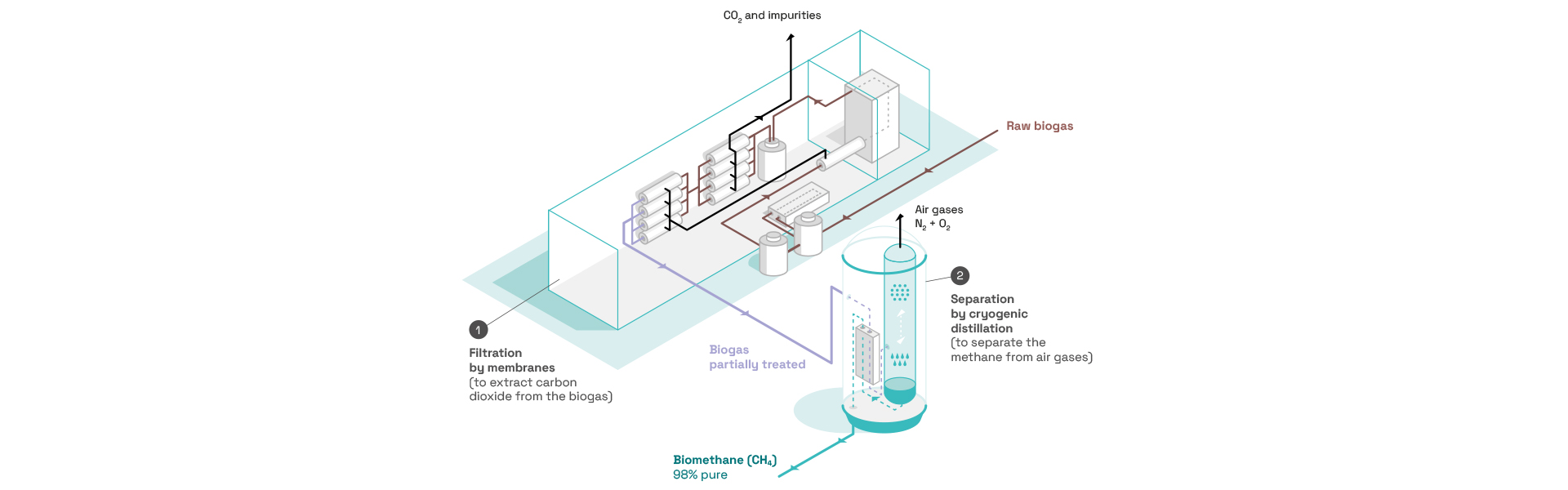

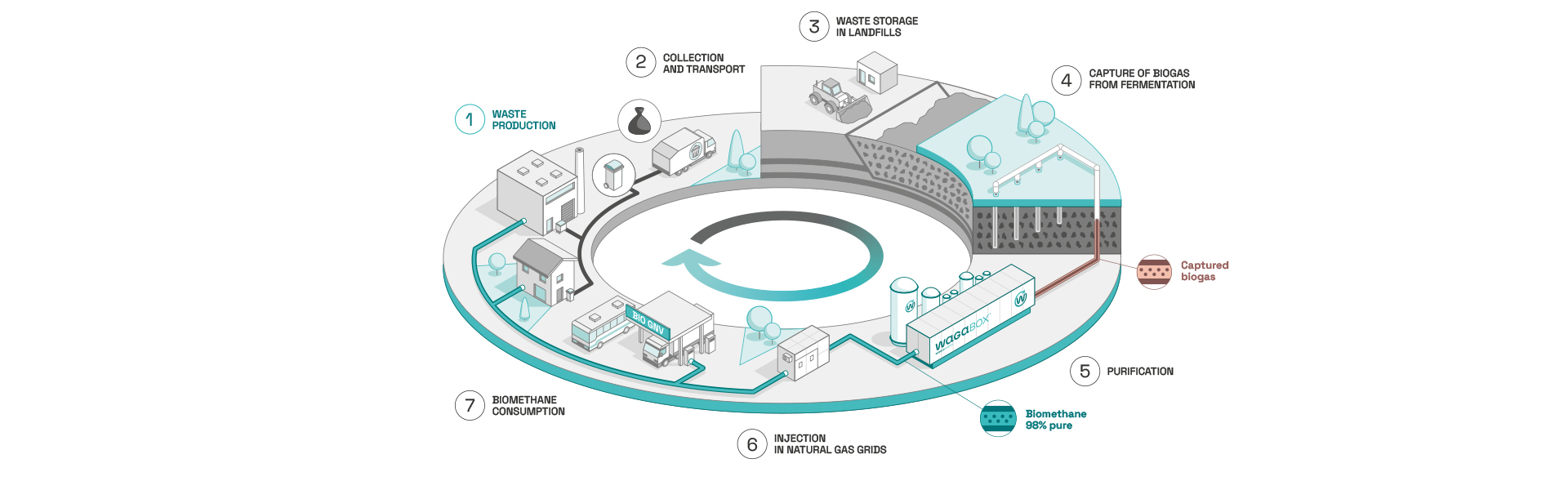

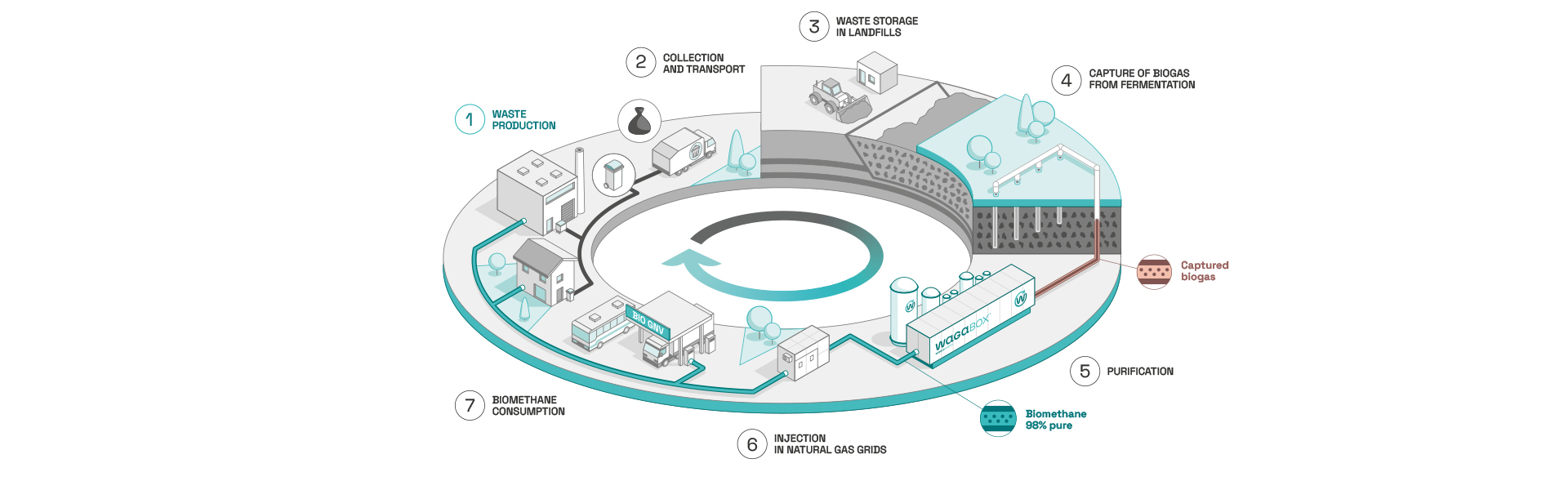

Developed and patented by Waga Energy, the revolutionary WAGABOX® technology makes it possible to convert landfill gas into renewable natural gas.

The WAGABOX® technology combines two cutting-edge systems for upgrading biogas derived from waste, ensuring that the RNG produced by our units meets the standards for injection into natural gas pipelines.

The WAGABOX® technology creates new opportunities for landfill gas recovery that combine energy generation, environmental compliance, and economic benefits.

The WAGABOX® technology is already in use at multiple landfill sites around the world owned by local authorities and leading waste management companies.

From Local Resources to Clean Energy: Scott County and Linwood’s Circular Economy Project

Scott County, Linwood Mining and Minerals, and Waga Energy announce the start-up of a Renewable Natural Gas facility at the Scott Area Landfill in Iowa

On October 7thth, 2025, the Waste Commission of Scott County, Linwood Mining and Minerals, and Waga Energy announced the start-up of a Renewable Natural Gas (RNG) production facility at the Scott Area Landfill in Davenport, Iowa. The project marks a major milestone in delivering locally produced renewable energy to the community while significantly reducing on-site greenhouse gas emissions.