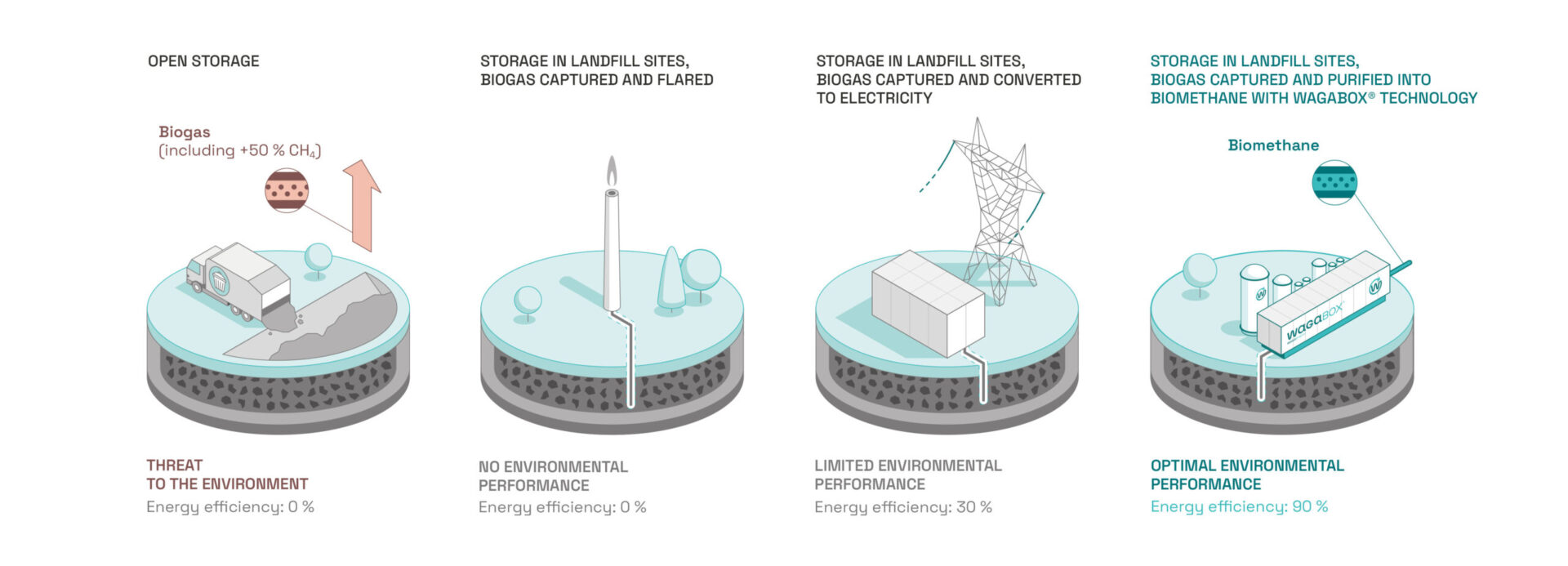

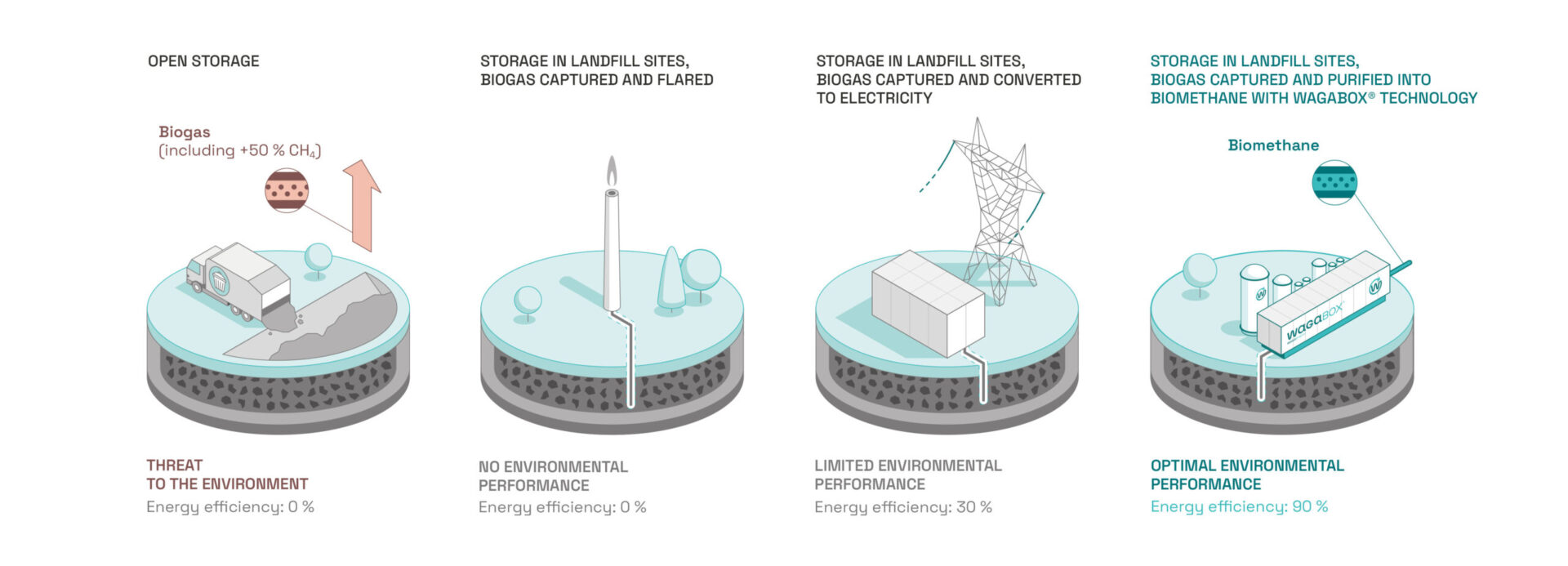

Converting biogas captured at landfills (landfill gas) into RNG offers an energy yield that is 2–3 times greater than solutions that involve converting biogas into electricity generation and heat. This method is far more efficient than traditional electricity generation from fossil fuels, making RNG a cleaner and more sustainable option.

Renewable natural gas is injected directly into existing natural gas distribution infrastructure, replacing fossil fuels, and reducing greenhouse gas (GHG) emissions by up to 90%.

Used as a compressed natural gas (CNG), RNG derived from biogas produced by waste also helps reduce carbon dioxide emissions by 80% compared with diesel, and cuts fine-particle emissions by 95% and nitrogen oxides (NOx) and nitrogen compounds by 50% compared with gasoline or diesel.

This technology also prevents landfill gas emissions from releasing potent greenhouse gases, ensuring environmental compliance and minimizing overall emissions from waste decomposition.

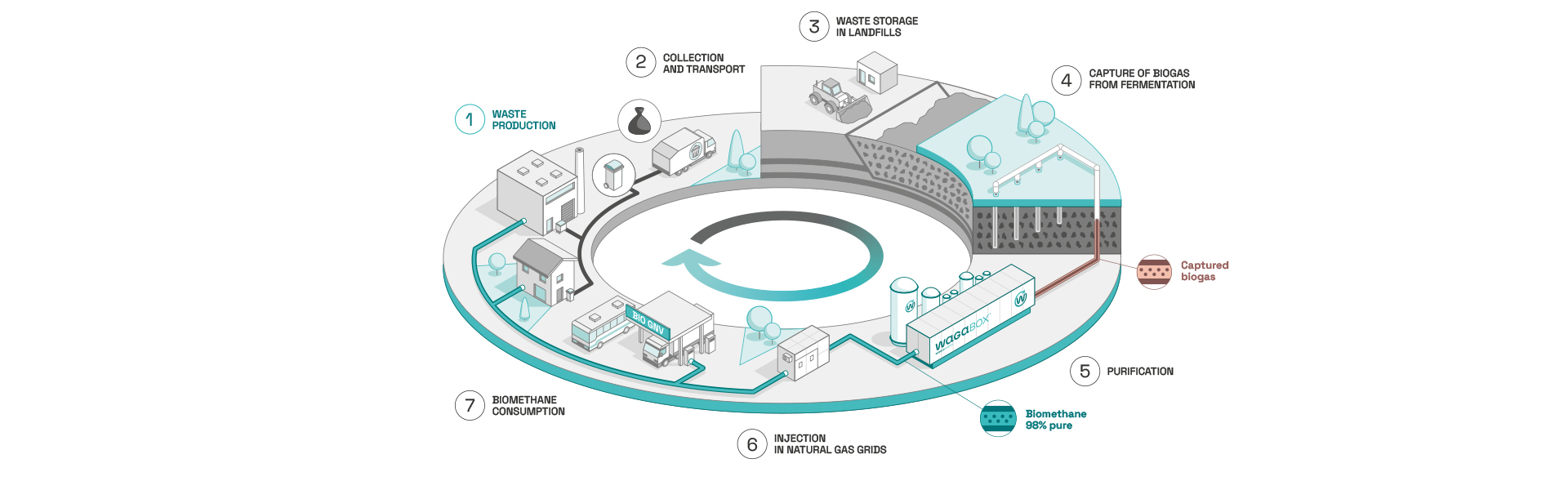

The production of RNG at a landfill site supports the circular economy. Consumption by residents and businesses produces solid waste that is collected and stored in solid waste landfills. Proper management of solid waste ensures that valuable gases like biogas and landfill gas can be efficiently captured and converted into renewable energy.

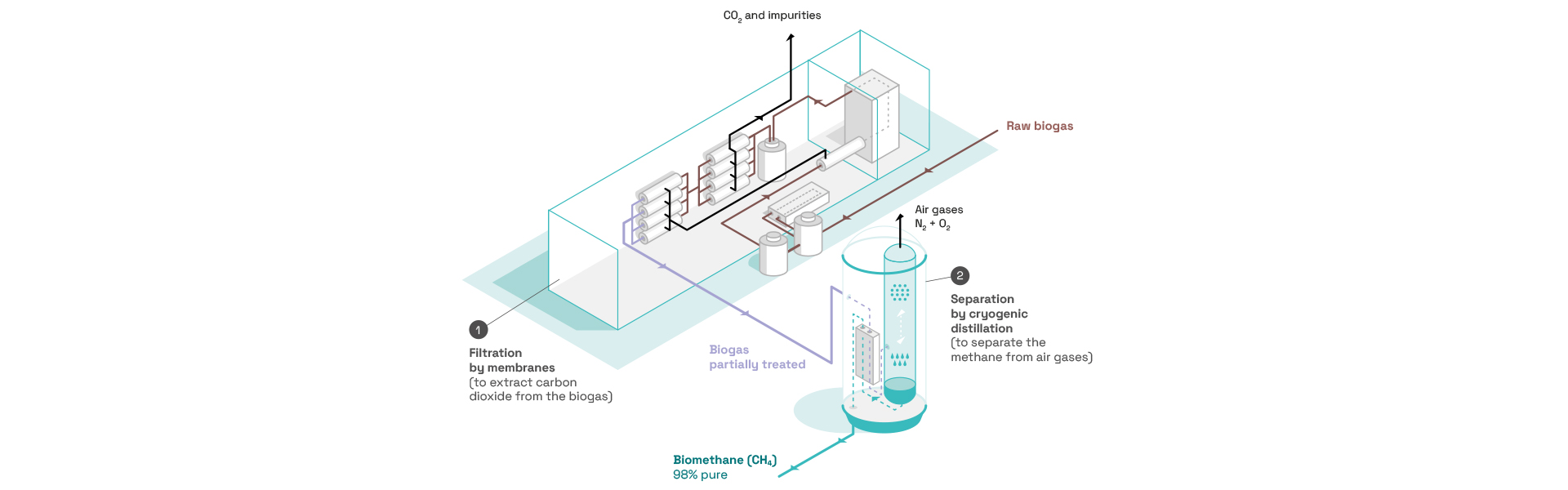

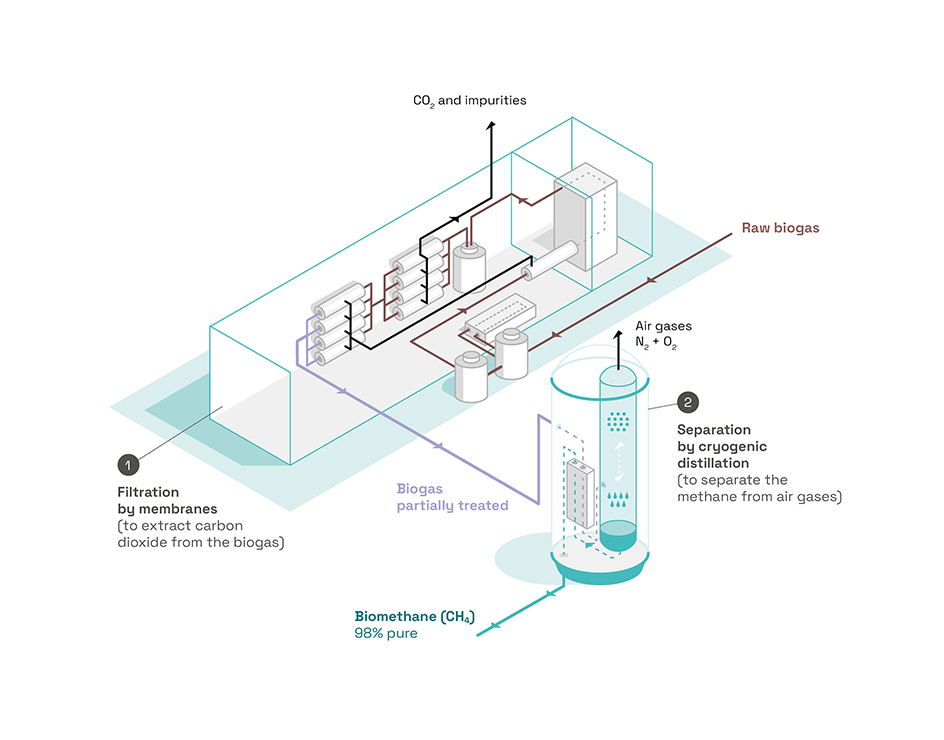

The organic matter in this waste decomposes and produces a mixture of gases known as biogas, composed mainly of methane and carbon dioxide, along with other organic compounds and hydrocarbons. This biogas can be captured efficiently using advanced landfill gas recovery systems. Once recovered, the landfill gas is purified and converted into renewable natural gas (often referred to as biomethane) before being redistributed to consumers via the existing gas infrastructure, or used locally as compressed natural gas (CNG).

RNG produced from biogas derived from landfill gas is the most competitive on the market. Many experts note that landfill methane is a potent greenhouse gas, but with innovative technology, it can be turned into a useful and rich gas source for energy.

RNG derived from landfill gas provides a local, renewable, and immediately available source of energy to accelerate decarbonization and a transition to cleaner energy. Our WAGABOX® projects promote local energy independence and a circular economy. With the innovative WAGABOX® solution, landfill gas can be converted into RNG.

Maximize your energy generation and environmental compliance.

With the innovative WAGABOX® solution, landfill gas can be converted into RNG.

We support our partners in producing a renewable and useful source of energy, providing them with a consistent and long-term revenue stream. Developed and patented by Waga Energy, the revolutionary WAGABOX® technology makes it possible to convert landfill gas and biogas into renewable natural gas.

Developed and patented by Waga Energy, the revolutionary WAGABOX® technology makes it possible to convert landfill gas into renewable natural gas.

The WAGABOX® technology combines two cutting-edge systems for upgrading biogas derived from waste, ensuring that the RNG produced by our units meets the standards for injection into natural gas pipelines.

The WAGABOX® solution offers significant economic and environmental advantages to help landfill site operators transform landfill gas from a liability to a resource by reducing landfill gas emissions and recovering its high methane content.

The WAGABOX® technology is already in use at multiple landfill sites around the world owned by local authorities and leading waste management companies.

Waga Energy makes a difference for waste management companies and local authorities

The WAGABOX® solution offers significant economic and environmental advantages to help landfill site operators transform their landfill gas from a liability to a resource.

Waga Energy handles all financing and on-site activities, such as the feasibility studies to the connection to the gas distribution pipeline.

The RNG produced by a WAGABOX® unit is marketed under a long-term contract with an energy off-taker, providing reliable and additional revenue for the landfill operator.

The standardized WAGABOX® solution is compatible with landfills of various capacities, starting at 500 scfm of collected landfill gas.

Our teams typically deploy WAGABOX® units within 12-24 months from contract signing, with the timeline influenced by local permitting and gas interconnection construction requirements.

The WAGABOX® technology is efficient, performing regardless of the quantity and quality of the landfill gas being treated.

This reduces the risk of unwanted emissions and odors, while maximizing revenue for landfill operators when compared to alternative upgrading solutions.

WAGABOX® units operate 24/7, are fully automated, and controlled remotely by expert technicians. Their performance is optimized every day through the collection of 300,000 data points transmitted by more than 200 sensors installed on the units. Predictive, preventive, and corrective maintenance processes are managed by specialized operators.

The WAGABOX® solution contributes to the development of a circular economy: RNG produced locally from household and industrial waste at the landfill site is injected into the natural gas pipelines to supply local homes and businesses. This provides local communities the opportunity to achieve energy independence, while reducing waste management costs and effectively combatting global warming.

Develop a virtuous, sustainable project

1. Analysis of renewable natural gas production potential from the landfill

Waga Energy performs pre-project studies and technical, economic, and regulatory feasibility analyses prior to implementation to obtain required administrative permits for producing and commercializing RNG. All parameters are shared transparently with the site operator and incorporated into the agreement between Waga Energy and the landfill operator.

2. Construction and installation of the WAGABOX® unit

Waga Energy manages all phases of construction and installation of the WAGABOX® unit. Site specifications, RNG production potential, landfill gas specifications, and RNG offtakes are analyzed prior to construction. Once civil engineering work is completed, and the equipment has been delivered to the site, Waga Energy’s technicians assemble the WAGABOX® unit. Standardized components and processes produce a faster installation timeline. Waga Energy is supported by a solid network of industrial, commercial, and financial partners, and covers all investments required to install, operate, and maintain WAGABOX® units.

3. Connection to the gas collection system and natural gas pipelines

Waga Energy ensures the dual connection of the WAGABOX® units. Connection is established upstream to the landfill gas collection system installed at the landfill, and the downstream connection is then established at the injection point on the natural gas distribution network.

4. Operation and maintenance

Fully automated and remotely controlled, WAGABOX® units operate 24/7 with a proven availability to exceed a 95% uptime. Waga Energy operates and maintains these units with the support of expert technicians working remotely or on-site. Data collected from all WAGABOX® units enables us to continuously improve energy and environmental performance.

5. Renewable natural gas sales

The landfill site operator, whether private or public, can choose between two types of partnerships with Waga Energy:

① Waga Energy is responsible for marketing the RNG produced by the WAGABOX® unit at the best price and shares royalties with the landfill.

② Waga Energy provides a service to operate and maintain the WAGABOX® unit and partners with the site operator, who markets the RNG on their own behalf.