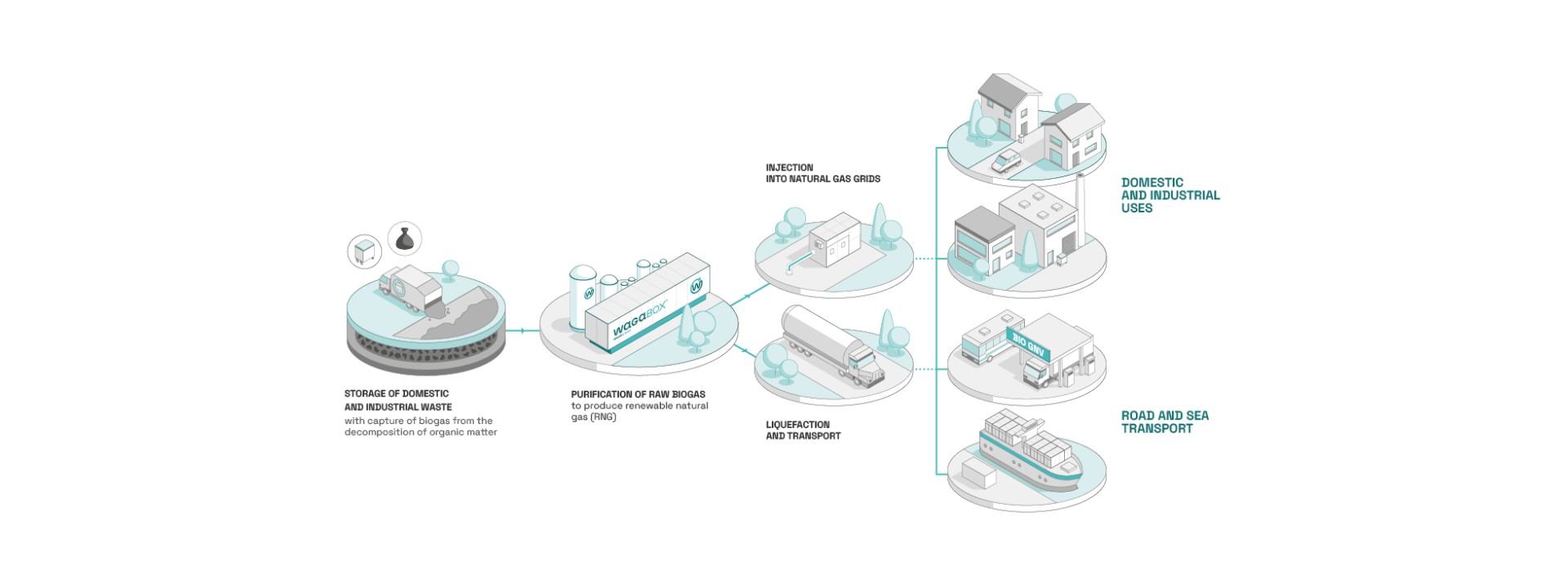

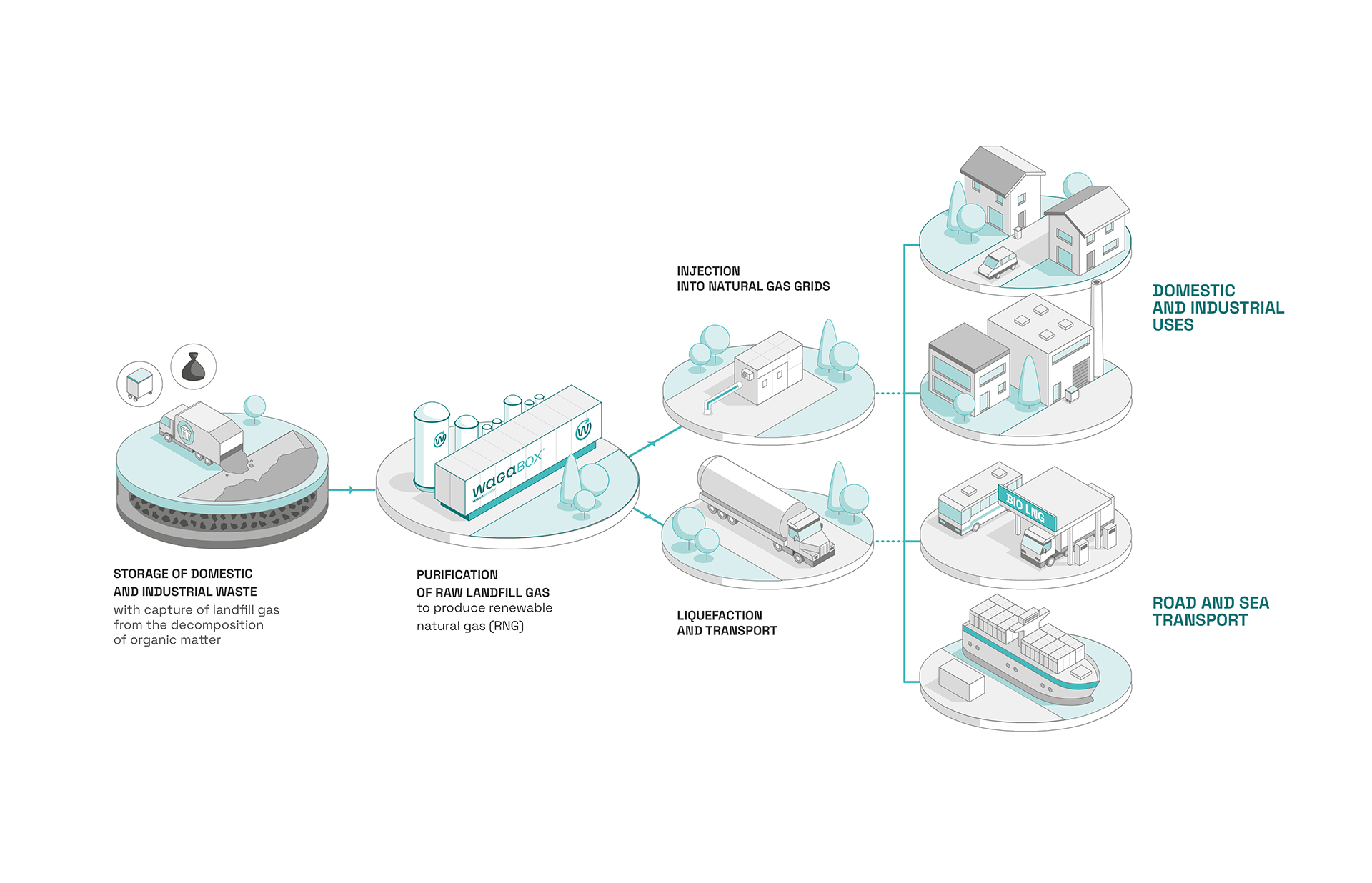

Waga Energy supplies biomethane produced using the innovative WAGABOX® purification technology under long-term BPA (Biomethane Purchase Agreement) contracts throughout the world.

The biomethane produced by the WAGABOX® units is a renewable drop-in replacement for fossil natural gas, in all its uses as a fuel.

Biomethane is a renewable substitute for fossil natural gas: with the same energy properties, it can replace it in all its uses as a fuel, both domestic and industrial.

Injected directly into the mains gas distribution network, biomethane replaces fossil natural gas, reducing up to 90% of greenhouse gas emissions.

Used as a biofuel (bioCNV), biomethane derived from landfill gas produced by waste helps to reduce CO2 emissions compared with diesel, provides a 95% reduction in fine particle emissions and a 50% reduction in nitrogen oxides (NOx) compared with petrol or diesel.

To expand the widespread development of biomethane as a substitute for fossil natural gas, we are committed to ensuring that its price is attractive for consumers.

The purification of biogas, a by-product of waste storage, made possible by the innovative WAGABOX® technology, enables us to produce biomethane at a competitive price.

It has other strategic advantages for buyers beyond its low environmental footprint: a stable production cost that is unaffected by fluctuations in other energy sources, and reduced transport costs because it is produced locally.

Whatever the size of the landfill site or the quantity of landfill gas processed by the WAGABOX® units, biomethane production volumes are predictable and regular.

These volumes are guaranteed to buyers via private (landfill gas Purchase Agreement) contracts in which Waga Energy enters into long-term commitments with its partners.

Waga Energy has its WAGABOX® production units certified to guarantee the quality, sustainability and conformity of the biomethane sold.

In Europe, WAGABOX® units with a production capacity in excess of 20 GWh are EU ISCC (International Sustainability and Carbon Certification) certified.

In North America, the biomethane produced by our WAGABOX® units allows us to generate Renewable Identification Numbers (RINs).

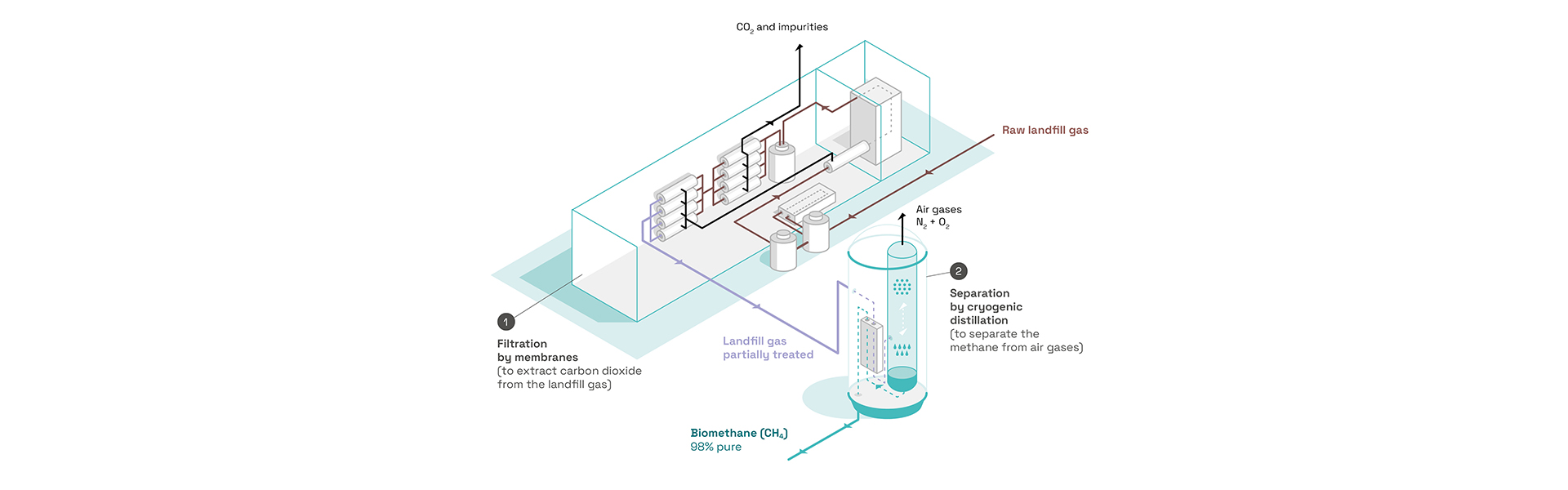

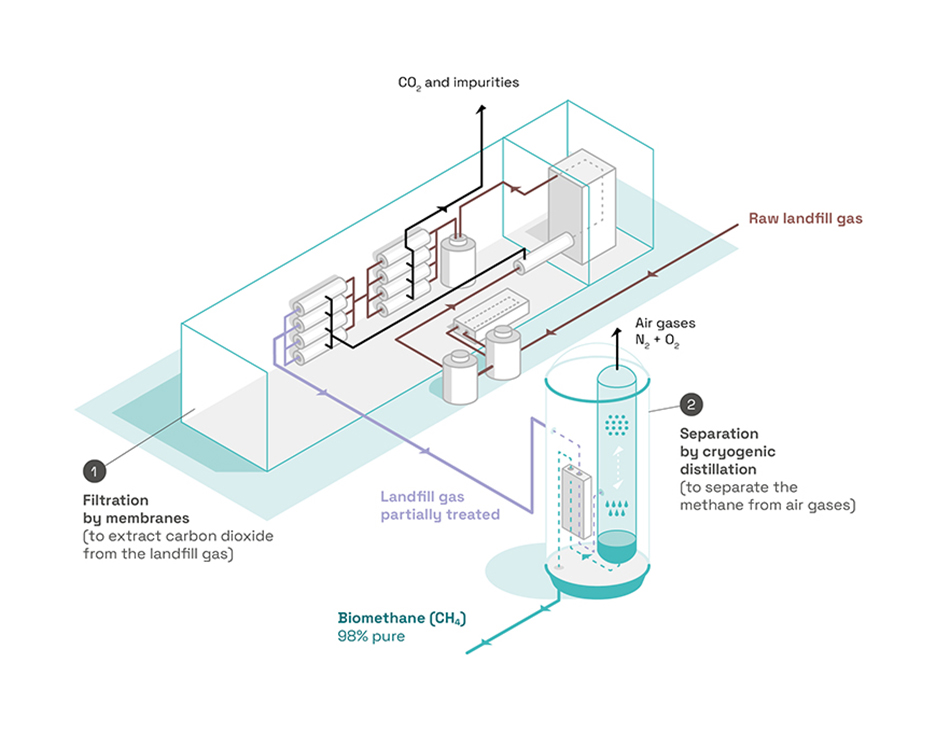

The reliable, high-performance WAGABOX® technology, developed using Waga Energy’s expertise in gas engineering, produces 98%-pure biomethane that is suitable for injection into biomethane networks.

Producing biomethane by purifying landfill gas from landfill waste is a technological feat made possible by the innovative WAGABOX® solution developed and patented by Waga Energy.

Thanks to the combination of two cutting-edge technologies for purifying landfill gas from waste, the biomethane produced by the WAGABOX® units is 100% suitable for injection into distribution networks, replacing biomethane of fossil origin:

Already in use at dozens of landfill sites around the world operated by local authorities and leading landfill site operators, WAGABOX® technology opens up new opportunities for recovery, combining energy, environmental and economic performance.