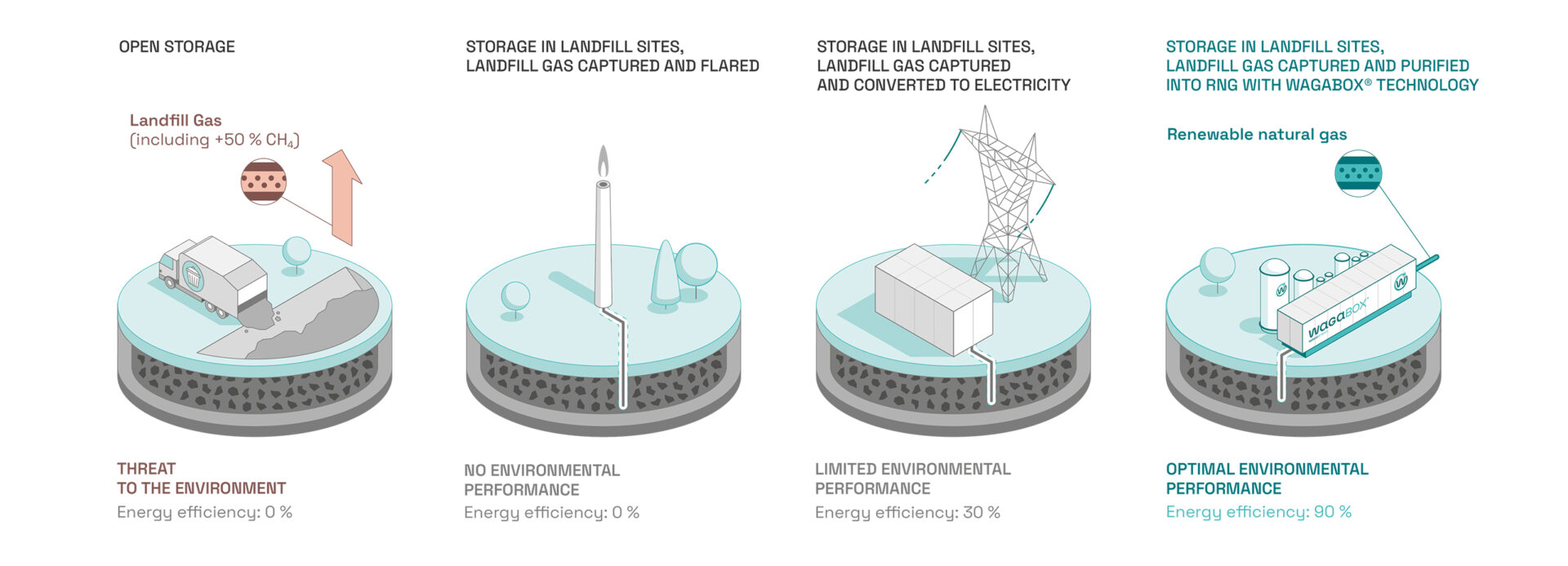

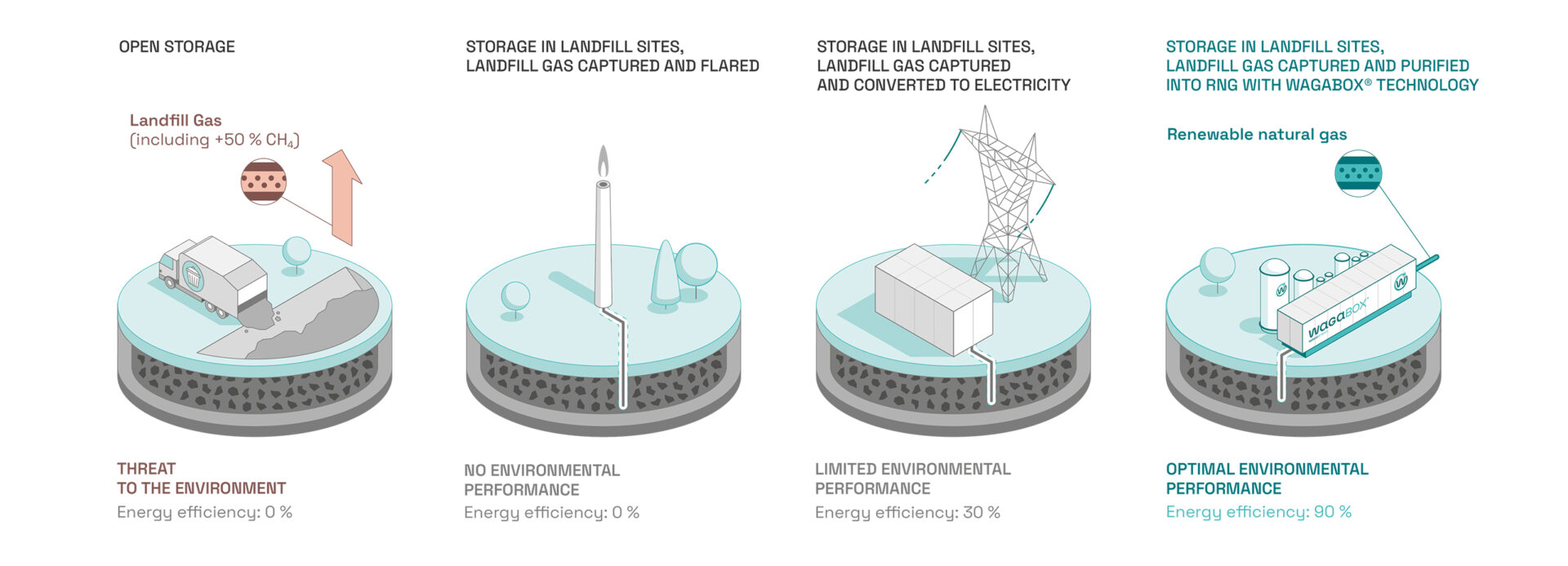

Converting the landfill gas captured at waste storage sites into biomethane offers an energy yield that is two to three times greater than solutions that involve converting landfill gas to electricity .

Injected directly into natural gas distribution networks, biomethane replaces natural gas, reducing greenhouse gas (GHG) emissions by up to 90%.

Used as a biofuel (bio-CNGNG), biomethane derived from landfill gas also reduces CO2 emissions by 80% compared with diesel and cuts fine particle emissions by 95% and nitrogen oxides (NOx) by 50% compared with petrol or diesel.

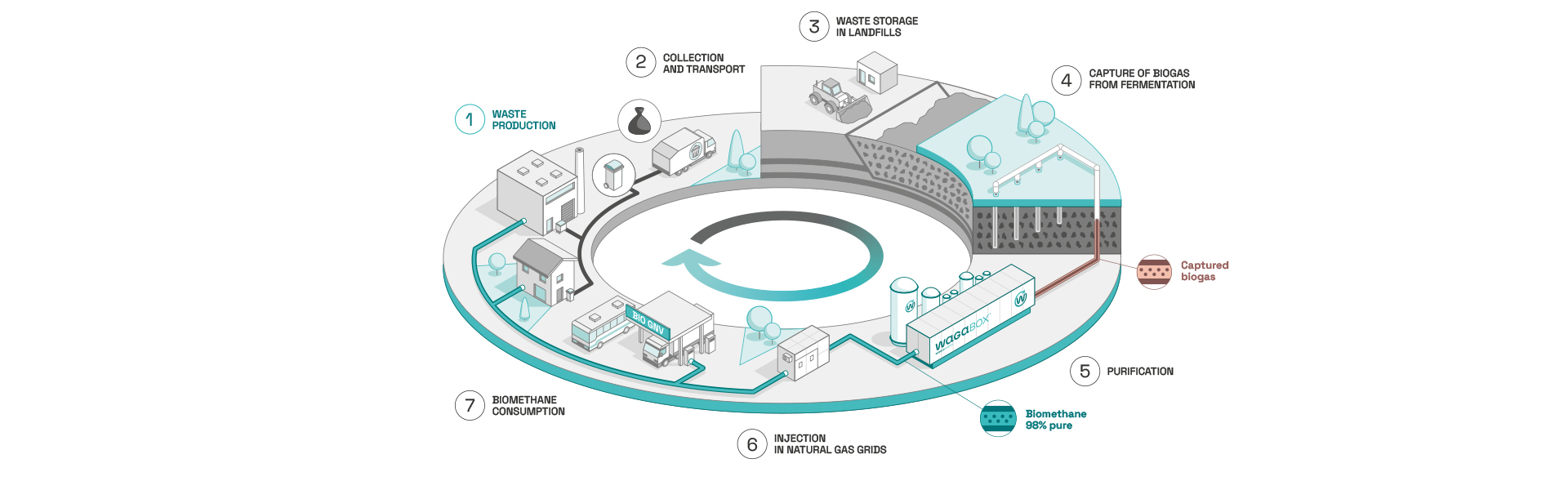

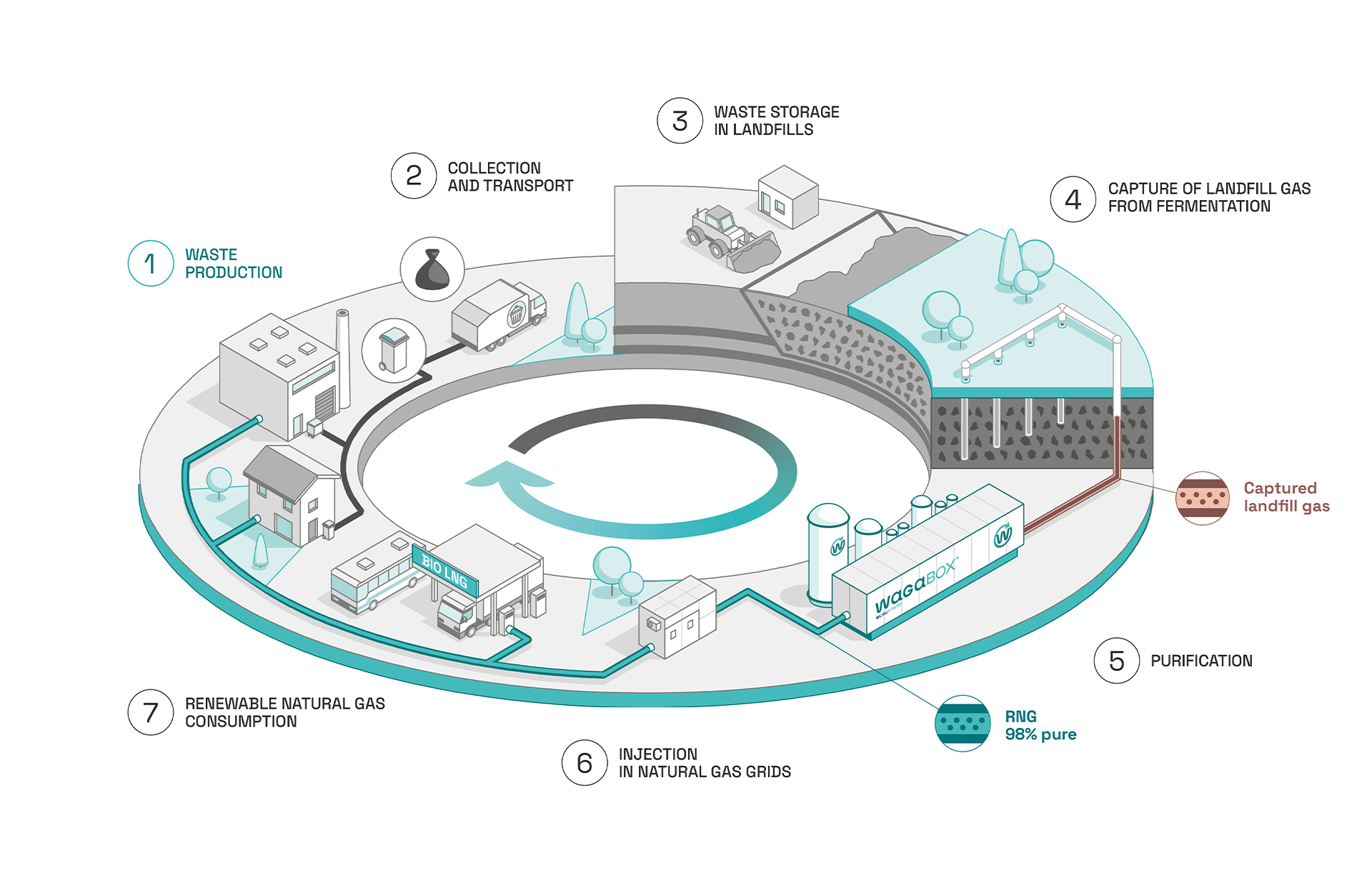

The production of biomethane at a landfill site is a virtuous cycle: domestic, commercial and industrial consumption produces organic waste, which is collected and stored in non-hazardous waste storage facilities (landfills). The organic matter contained in this final waste decomposes and produces a mixture of gases known as landfill gas.

Once recovered, the landfill gas is purified and converted into biomethane, before being redistributed to consumers via the existing gas infrastructure or used locally ias biofuel. Biomethane produced from landfill gas is the most competitive on the market.

Producing biomethane from landfilled waste provides local authorities with a local, renewable and immediately available source of energy to accelerate decarbonisation and the energy transition. Our projects promote local energy independence, and will support the United Kingdom in achieving Net Zero targets.

Boost your energy and environmental performance

Thanks to the innovative WAGABOX® technological solution, landfill site operators can now convert their recovered landfill gas into biomethane.

Our partners are producers of useful, renewable energy, the commercialisation of which provides them with a regular, long-term income.

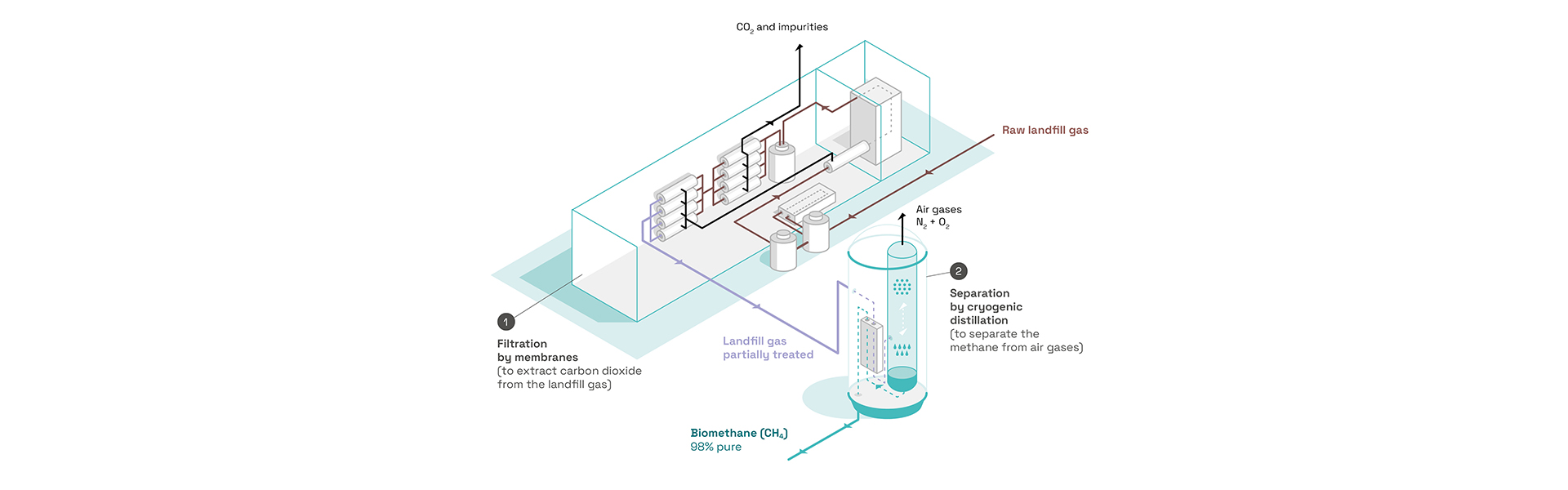

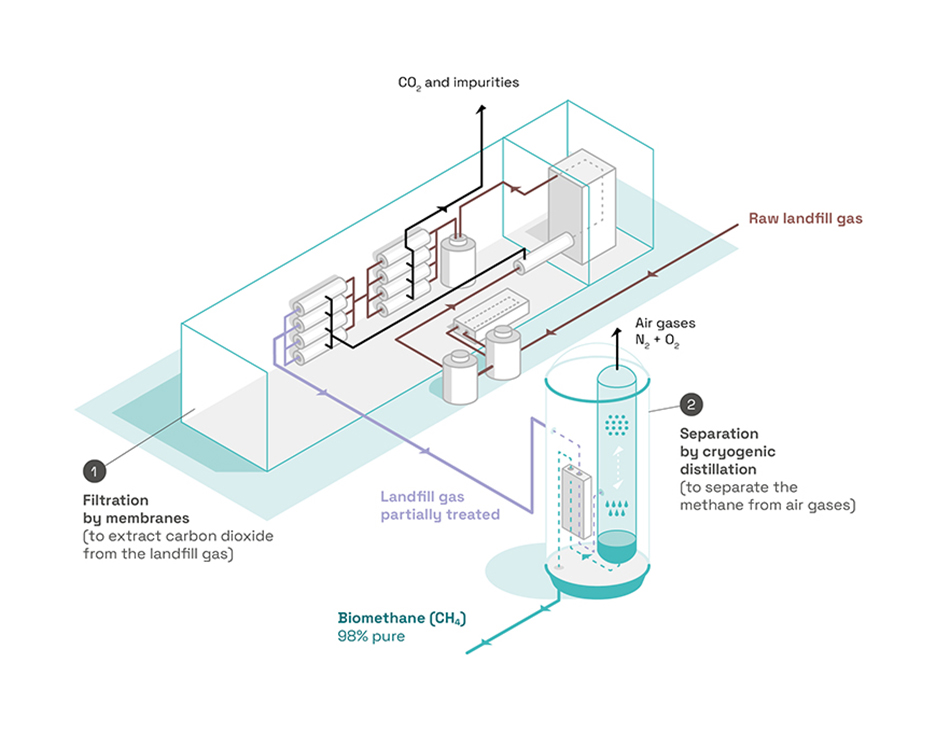

Developed and patented by Waga Energy, the groundbreaking WAGABOX® innovation makes it possible to convert landfill gas into biomethane.

Thanks to the combination of two cutting-edge technologies for purifying landfill gas, the biomethane produced by the WAGABOX® units is 100% suitable for injection into distribution networks, replacing natural gas of fossil origin:

Already in use at dozens of landfill sites around the world operated by local authorities and leading landfill site operators, WAGABOX® technology opens up new opportunities for recovery, combining energy, environmental and economic performances.

How it makes a difference

for waste management companies and local authorities

The WAGABOX® solution offers various economical and environmental advantages to support landfill site operators to transform their activities and to become renewable energy producers:

Waga Energy can take care of all the financing and on-site activities, from feasibility studies for the installation of a WAGABOX® unit to connection to the gas distribution network, including the installation of landfill gas extraction modules and compliance tests for the gas network.

The biomethane produced by a WAGABOX® unit at a landfill site is marketed under a long-term contract with an energy offtaker. Therefore, it generates regular, additional revenue for the non-hazardous waste storage facility operator.

The WAGABOX® solution is industrial, standardised and available in several ranges to suit all sizes of non-hazardous waste storage facilities, from 150 m3/h to 20,000 m3/h of landfill gas emitted by a site.

Our teams deploy and commission WAGABOX® units within 12 to 24 months from signing the contract, depending on how long it takes to obtain the necessary local permits.

WAGABOX® technology is unaffected by the air content in the captured landfill gas , and offers excellent performance whatever the quantity and quality of the landfill gas.

This wide quality range offers the landfil opator a major advantage: it reduces the risk of fugitive emissions and odours, and maximises revenue for landfill operators compared with other recovery solutions on the market.

Fully automated and remotely controlled by expert technicians, our WAGABOX® units operate 24 hours a day, 7 days a week. Their performance is optimised every day thanks to 300,000 data points transmitted by more than 200 sensors. The maintenance regime which combines predictive, preventive and curative maintenance is carried out by a regional network of specialist operators.

The WAGABOX® solution contributes to the development of a circular economy: Wastes produced locally from households and businesses is stored in a landfill site, then the biomethane is injected into the local gas network to supply homes and businesses in the region.

This gives local authorities and waste managers a tool for achieving energy independence and raising the profile of their region, while reducing the cost of waste management and effectively fighting global warming.

Develop a virtuous and sustainable project

1. Study of the biomethane production potential of the non-hazardous waste storage facility and contracting

Waga Energy carries out pre-project studies and technical, economic and regulatory feasibility analyses prior to implementing projects in order to obtain the administrative permits required for the production and commercialisation of biomethane. All the parameters are shared transparently with the site operator, and incorporated in the preparation of the framework contract between Waga Energy and its partners.

2. Construction and installation of the WAGABOX® unit

Waga Energy engineers the project, taking into account the technical specifications of the site, support schemes for renewable energy production, production potential, using a robust, controlled industrial process. Once the civil engineering work has been completed and the equipment has been built and delivered to the site, our specialist technicians assemble the WAGABOX® unit on site. The standardisation of components and processes means that installation can be completed within an optimised time frame. Supported by a solid network of industrial, commercial and financial partners, Waga Energy covers all the investment required to install, operate and maintain the WAGABOX® units.

3. Connection to the gas collection system and gas networks

Waga Energy ensures the dual connection of WAGABOX® units: upstream to the landfill gas collection system installed at the landfill, after optimisation to maximise efficiency and environmental performance; downstream to the injection point on the municipal gas network

4. Operation and maintenance

Fully automated and remotely controlled, WAGABOX® units operate 24/7 with a guaranteed availability of at least 95 %. Waga Energy operates and maintains its units with the support of expert technicians, working remotely or on site. The data collected daily from all WAGABOX® units enables it to continuously improve the energy and environmental performance of its installations.

5. Biomethane sales

The operator of a landfill site, whether private or public, can choose between two types of partnerships with Waga Energy:

① Waga Energy is responsible for marketing the biomethane produced by the WAGABOX® unit at the best price and shares royalties with the landfill.

② The site operator markets the biomethane on its own behalf in partnership with Waga Energy, which then provides a service for the operation and maintenance of the WAGABOX® unit.